| «~µPˇGŞâĄiĽÖ | łW®ćˇG | §÷˝čˇGĽĐ·Ç |

| ˛Ł¦aˇG¬ü°ę |

ALLOY 7075¶i¤f¬ü°ęľT´Îˇ]ąęŞ«ąęąĎ©ç·ÓˇAµsĄÎĄ˛¨sˇ^

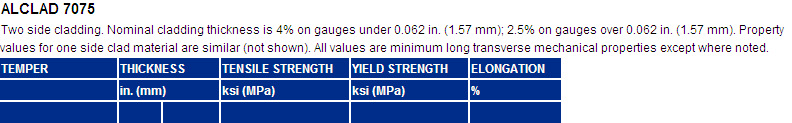

Introduced by Alcoa in 1943, alloy 7075 has been the standard workhorse 7XXX series alloy within the aerospace industry ever since.

It was the first successful Al-Zn-Mg-Cu high strength alloy using the beneficial effects of the alloying addition of chromium to develop

good stress-corrosion cracking resistance in sheet products. Although other 7XXX alloys have since been developed with improved

specificproperties, alloy 7075 remains the baseline with a good balance of properties required for aerospace applications.

Alloy 7075 is available in bare and alclad sheet and plate product forms in the annealed state as well as several tempers

of the T6, T73 and T76 types.

«ČŞAĄNŞí˝Đ¬d¬d¤Gşű˝X

«ČŞAĄNŞí˝Đ¬d¬d¤Gşű˝X

Alloy 7075 sheet and plate products have application throughout aircraft and aerospace structures where a combination of high strength with moderate toughness

and corrosion resistance are required.

Typical applications are alclad skin sheet, structural plate components up to 4 inches in thickness and general aluminum

aerospace applications.

Note: Value maximum if range not shown.

ALLOY 7075ľT´Î¤ÎľTŞO˛Ł«~¨ĎĄÎ®×¨Ňˇ]˝Đ¬d¬Ý¤U±qłć¬yµ{ˇ^

µL«áĹU¤§Ľ~ŞşłĆłf·ÇłĆˇA§Ú̦łąę¤OˇI

µL«áĹU¤§Ľ~ŞşłĆłf·ÇłĆˇA§Ú̦łąę¤OˇI

Ą»¤˝ĄqĄHˇ§«~˝č¦Ü¤WˇA«Č¤áşˇ·NˇA«ůÄň§ď¶iˇA¸Ű«H¸gŔ硨¬°˝č¶q¤č°wˇA¤˝ĄqąB§@ÄY®ćżí´`ˇG2000°ę»ÚĽĐ·ÇŞşn¨DˇA¤˝ĄqľÖ¦ł±M·~ŞşľP°â¶¤ĄîˇAŻŕµą«Č¤á´Ł¨Ń±M·~¤ĆŞşŞA°ČĹé«YˇC

ŞF˛đĄ«ŞF·~¤j©ÝŞ÷Äݦł¤˝Ąq¦ě©óŞF˛đĄ«˛M·Ë¤T¤¤Ş÷Ŕs¤u·~°ĎˇA˛M·Ë¤T¤¤Ü®w±żn4000Ą¤č¦ĚˇA«Oµ|°ĎÜ®w1400Ą¤č¦ĚˇAŞęŞů¤Ŕ¤˝ĄqÜ®w1000Ą¤č¦ĚˇAĄi¸gŔç§Kµ|ÜŔxĄ[¤uˇA¬°«Č¤á´Ł¨Ń¤Î®É©P¨ěŞş˛Ł«~©MŞA°ČˇC

ŞF˛đĄ«ŞF·~¤j©ÝŞ÷Äݦł¤˝Ąq¬°¤Fşˇ¨¬©MÂX¤j°ę¤şĄ«łő»Ý¨DˇAŞşŞA°Č©ó˛{ĄN¤ĆŞşĄř·~ˇA¤˝ĄqĄi¬°«Č¤á´Ł¨Ńˇ§ąs®w¦sˇ¨¤Îˇ§Şů¨ěŞůˇ¨Şşˇ§¤@Ż¸¦ˇˇ¨ŞA°ČˇAŻuĄżĹé˛{ˇ§ĄH«Č¤á¬°¤¤¤ßˇ¨Şş¤˝Ąq¸gŔç˛z©ŔˇC

ĄDŔ粣«~

AA5052ˇBAA5083ˇBAA5754ľT¦XŞ÷ŞO§÷

AA7075ˇBAA7050ˇBAA2024ˇBAA6061ľT¦XŞ÷ŞO§÷ˇB´Î§÷ˇB±ř§÷

3ˇBĽŇ¨ăľTAA7122 ˇB¶WĄŞOPLANOXAL50

§ÚĚŞş«Č¤á

¨´¤µ¬°¤îˇA§Ṳ́w¦¨Ą\¦a¬°¦h®aŻčŞĹˇAŻč®üˇA»´«¤u·~»â°ěµĄŞş«Č¤á´Ł¨Ń¤FŞş˛Ł«~©M§ąµ˝ŞşŞA°ČˇAło¨ä¤¤Ą]¬AˇG

ŻčŞĹ§@·~ˇG¦¨¸ˇB¨H¸ˇB¦č¸¤u·~¶°ąÎˇB°ę¨ľŻčŞĹ¤Q¸ą¶µĄŘˇBŞ˝¤QˇB¶W¤CˇB3¸ą¤Î5¸ą¶µĄŘˇBŞiµ¶µĄŘµĄ

Żč®ü§@·~ˇGĽs¦{Ą«¶Ŕ®Hły˛îĽtˇB¦ż«nły˛îĽtˇB«nµŘ°Şłt¸Ą¦ł¤˝ĄqµĄ

ĄćłqąBżé·~ˇGŞüş¸´µłqˇB¦čŞů¤lµĄ

¤u·~¤Ş÷ˇGMotorolaˇB´I¤h±dˇB¸§Q®úˇB¶lłqµĄ

¶WÁn¦ć·~ˇGĄ˛Żŕ«HˇB¬ě«Â«HµĄ¦ż®ýş¸fĽt°Ó

ĽŇ¨ă¦ć·~ˇG¦č©¬ˇBSidelˇB¶®µXµĄ

¦X§@¤č¦ˇ

®w¦słĆłfˇGĄiĄH±ÄĄÎ¨ŃŔł°ÓşŢ˛z®w¦sŞş¤č¦ˇˇC

¦X§@Şě´ÁˇA¶QĄqĄiľA·í¦b§ÚĄq±ÄÁʲ{łf®w¦s§÷®ĆˇA§@¬°¤F¸Ń§ÚĄq§÷®Ć©MŞA°ČŞş¤@Ó¶}©lˇC¸gąL¶QĄqŞş¨ŃŔł°Ó»{Ąi«áˇA¶Q§ÚÂů¤čĄiñ©w¦X§@¨óÄł¶i¦ćłĆłfˇC

Ą»¤˝Ąq±Ä¨ú¶µĄŘ¸g˛zˇ§¤@Ż¸¦ˇˇ¨ŞA°ČˇA«Č¤á¦łĄô¦ó°ÝĂDĄu»Ý¦P¶µĄŘ¸g˛zŞ˝±µÁp«YˇA´î¤ÖłB˛z°ÝĂD©µ»~®É¶ˇˇC

·ŔI¤Ŕľá

Ą»¤˝Ąq¦b°ęĄ~ľÖ¦łĽsŞxŞşµ¦˛¤Áp·ůˇAĄi±q¤Ł¦PŞşĽt®aqłfˇAÁקK¦]¬°¬Y®aĄÍ˛Ł°Ó¦]¬°ĄÍ˛Ł±Ć´Á°ÝĂD¦Ó©µ»~qłćˇF

§ÚĄq»P¤Ł¦P«Č¤á«ŘĄßŞř´ÁĂ©wŞş¦X§@Ăö«YˇAşÉ¶q»P¦U«Č¤á¤@°_¨î©w®w¦słĆłf¤Î®ř¤Ć¤č®×ˇC

Ą«łőąw´ú

Ą»¤˝ĄqąďĄÍ˛Ł©P´ÁˇBĄ«łő»ů®ćĹܤĆÁͶդ©ĄH¤Î®ÉłqłřˇA¨ó§U«Č¤á¦bľA·íŞş®ÉÔ©µŞř¦X¦P©MĄ[¤jŔxłĆ¶qˇAłWÁץ«łő·ŔIˇC

°â«áŞA°Č

«Č¤á¦pąď§÷®Ć˝č¶q¦łĄô¦ó˛§ÄłˇAĄi»P§ÚĄq¶µĄŘ¸g˛z·ľłqˇC§ÚĄq§ŢłN¤ä±ÂłˇĄi´Ł¨ŃĄ[¤u¤Î¨ĎĄÎ«ŘÄłˇC¦p˝T©w¬O§ÚĄq˝č¶q°ÝĂDˇA˝Đ¶QĄqşÉ¶q«O«ů§÷®Ć§ąľă¤ŁłQ¨ĎĄÎˇA§ÚĄqĄiĄH°h´«łfˇC¤@Żë°â«áĹTŔł®É¶ˇ¦b¤ş2¤Ń¤şµą¤©¦^´_¤ÎłB˛zˇC

§ó¦h¸Ô±ˇ˝Đµn¤J©x¤č»{ĂҸ۫HşôŻ¸ˇGwww.alcoa-dydt.com

¬üľTALCOA¨ľ°°żë»{˝Đµn¤J:http://www.alcoa-dydt.com/html/product1/

§Ö¨ÓÁp«Y§Ú̧aˇ]400-666-4378ˇ^

ŞF˛đĄ«ŞF·~¤j©Ý¦ł¤˝Ąqˇ]ľT§÷¨Ć·~łˇˇ^

Ąř·~Ľö˝uˇ]Telˇ^ˇG0769-82990080 20˝u

Ąř·~¶ÇŻuˇ]Faxˇ^ˇG0769-87288036 5ÓłˇŞů

ŞA°ČĽö˝uˇG400-666-4378

˛ľ°Ęąq¸ÜˇG13609689756ˇ]ÄÁ¤p©jˇ^

˛ľ°Ęąq¸ÜˇG13922917221ˇ]ŞLĄýĄÍˇ^

Ąř·~¶l˝cˇGliuping@alcoa-dydt.com

Ąř·~şôŻ¸ˇGhttp://www.alcoa-dydt.com

¦b˝uĄć¬yˇG2421050595