東業大拓大量供應7075鋁合金板_超寬鋁板_國標鋁板_7075鋁棒規格_AA7075鋁合金 (美國鋁業ALCOA,凱薩鋁業KAISER AA7075-T651,加拿大鋁業ALCAN超硬航空鋁板,國標西南鋁7075特厚鋁板_7075航空鋁板)8mm-500mm鋁合金板材及薄板0.5mm-5.0mm 圓棒φ3.0-460mm(有現貨AA5052(日本神戶制鋼KOBELCO4mm>-50mm鋁合金板材(有現貨),價格優惠,規格,服務周到,可按客戶所需尺寸裁切供貨,送貨準確及時,歡迎來電洽詢購買0769-82990080。

大量供應AA7075鋁材_咨詢7075鋁板價格_7075鋁板_7075鋁棒_A7075進口鋁材

東業大拓專業代理ALCOA進口鋁合金(產品優勢):

優點一:產品均符合ASTM標準,具有良好的組織致密性,確保產品無沙孔、橫紋、氣泡及雜質缺陷;

優點二:產品在400℃工作環境下不會產生變形,或在加工和受力時也不會翹曲、開裂及變形;

============================================

化學成分/%,不大於 | 其他雜質/%,不大於 | ||||||||||

合金 牌號 | 硅 Si | 鐵 Fe | 銅 Cu | 錳 Mn | 鎂 Mg | 鉻 Cr | 鋅 Zn | 鈦 Ti | 單個 | 總 和 | 鋁 Al |

7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | 餘量 |

機械性能分析(Typical Mechanical Properties) | ||||

鋁合號 及狀態 | 拉伸強度 | 屈服強度 | 硬度 | 延伸率 |

(250℃MPa) | (250℃MPa) | 500kg力10mm球 | 1.6mm(1/16in)厚度 | |

ALLOYAND TEMPER | Ultimate Tensile Strength | Ultimate Tensile Strength | Hardness | Elongation |

7075-T651 | 572 | 503 | 160 | 11 |

物理性能分析(Typical Physical Properties) | ||||

鋁合號 及狀態 | 熱膨脹係數 (20-100℃)um/m.k | 熔點範圍(℃) | 電導率20℃(68°F)(%ACS) | 電阻率20℃(68°F)m㎡/m |

ALLOY AND TEMPER | Average Coefficient Of Thermal Expansion | Melting Range | Electrical Conductivity | Electrical Resistivity |

7075-T651 | 23.6 | 475-635 | 33 | 0.0515 |

=============================================

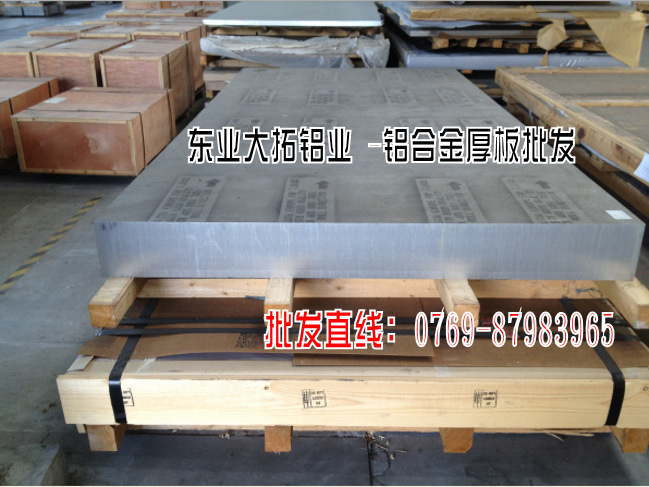

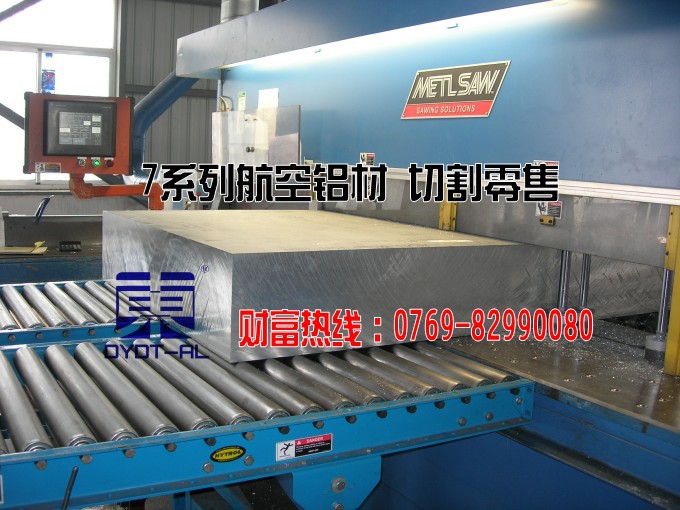

車間實拍圖片100%

7075航空鋁板產品特點:

航空鋁板與模具鋼相比,具有顯著的優點:

1. 重量輕。由於其密度只有一般模具鋼的36%,故運動慣性比較低,在生產過程中加,減速度均比較容易,能減低機器及模具的損耗。

2. 機械加工容易及尺寸穩定性高。其切削速度比一般模具鋼快6倍以上,故大量減低模具加工時間,令模具可更快進行生產。

3. 的熱傳導率。其熱傳導率比一般模具鋼高,故可節省模具在生產時的冷切時間50%,從而提高模具的生產效率。所以Alumold在注塑模、吹塑模、低壓模、橡膠模等不同模具行業80%的產品中有廣泛應用。

================================================

國標鋁合金與歐州鋁合金,在牌號與進口鋁對應的同時,質量是否也相同嗎?

總述:鋁材料產品在質量上不論是好是壞與生產技術、工藝、工業裝備水平、勞動者素質等綜合相關外,另外還有以下幾點因素有關:

A、不同的生產標準和規範下的產品質量因其要求不同而制定的

B、鋁合金產品在某些工藝處理及檢驗項目,如果需方沒有要求,供方則不提供,如此可造成產品性能有顯著的差異。如美鋁(Strait)產品中的可熱處理強化合金係列均經過內應力工藝處理,通過超聲波探傷檢驗、光譜分析、半導彎曲試驗、顯微腐蝕試驗、電磁(渦流)測試以及開裂敏感性試驗等項目,確保美鋁產品在市場的各個方面均出類拔萃

C、變形鋁或鋁合號中的數字只代表其純度或某些合金化學元素的平均百分含量

D、即使是化學成分含量,同一牌號的產品因其所依據的生產標準不同以及生產批次不同其品質也會有所不同

【服務周到,盡善盡美】東業大拓鋁業自2006年成立以來,為感謝客戶多年以來一如既往的支持與信賴,推出全新的服務:

加工部服務:可為客戶提供平板,切割,分條,表面拋光,氧化熱處理,貼模等加工服務;

儲運部服務:珠三角地區客戶,可免費送貨上門服務(省外代辦物流);

產品鄭重承諾:以質取勝,堅決不做不良品,對材質三保承諾,可開17%票,隨貨附帶原廠材質書SGS報告;

服務理念:公司市場定位明確,提供產品服務,能有效減少用戶購買產品的中間環節,減少客戶的不必要消費;

全程化跟蹤服務:公司擁有一支專業化管理團隊和規範化管理流程,同時為用戶提供產品全過程咨詢服務,保證用戶需求的實現;

=============================================

銷售部經理:13609689756

東業大拓(鋁材事業部)【已通過第三方機構實地認證】

認證旺鋪:http://www.alcoa-dydt.com

===================================================

選擇東業大拓的優勢:產品規格,庫存充足,長期現貨供應價格實惠,產品原廠包裝避免表面劃傷缺點,並附帶原廠材質證明及SGS報告。

選擇東業大拓材料是您的:東業大拓所售產品出廠前都必經過檢測部運用先進檢測設備嚴格評審後才出貨,不論是對產品的外觀,材質,板形,硬度,整體綜合嚴審合格出廠,真正做到讓客戶用的放心.