1060 | Ә¬әAЎGOЎBH14ЎBH24 | |

| Ө¶ІР Introduction | ||||||||||||

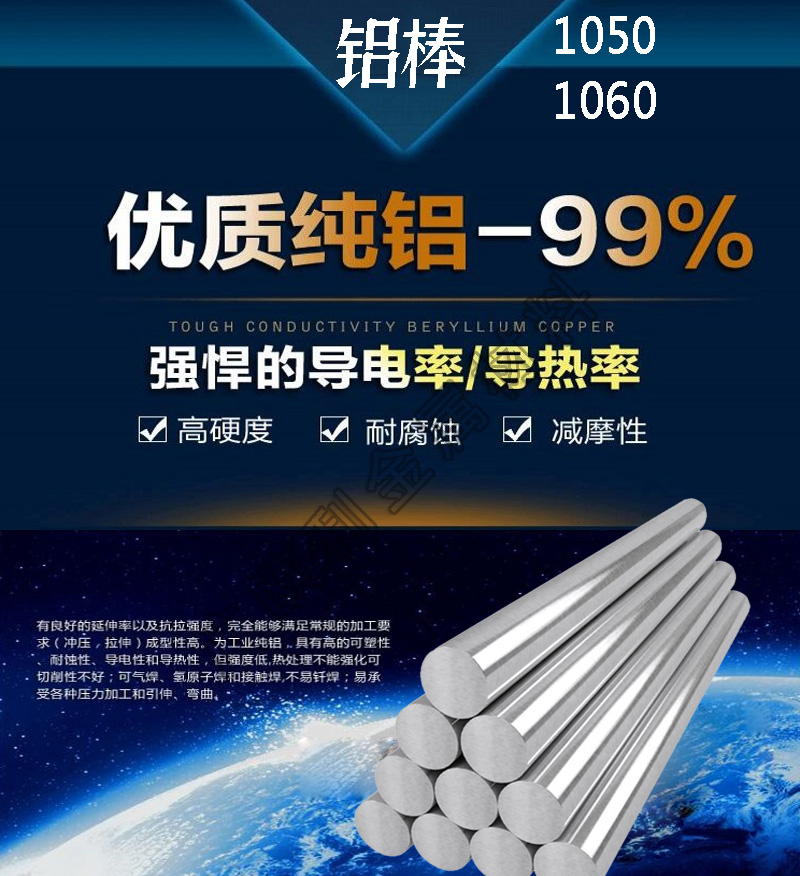

| 1060§tҫT¶q№FЁм99.6%ҘHӨWӨSіQәЩ¬°ҜВҫTЎAҰbҫTӘOұa®aұЪӨӨДЭ©уӨ@ҙЪұ`ҘОӘә«YҰCЎCҰ№«YҰCҫTӘOӘәӨWӯ·ЎG¬°ұ`ҘОӘә«YҰCЎAҘXІЈ№Lө{ӨсёыіжӨ@ЎA§ЮіN¬Ы№п©уӨсёыҰЁјфЎA»щ®ж¬Ы№п©уЁдҘҰҰXӘчҫTӘOҰіҘЁӨjӨWӯ·ЎCҰіЁ}ҰnӘә©өҰщІvҘHӨО§Ь©Фұj«ЧЎA§№ҘюҜа°чӘҫЁ¬ұ`іWӘәҘ[ӨuӯnЁDЎ]ҪДАЈЎA©ФҰщЎ^ҰЁ«¬©К°ӘЎC¬°ІЈ·~ҜВҫTЎAЁгҰі°ӘӘәҘi¶м©КЎBӯ@»k©КЎBҫЙ№q©К©MҫЙјц©КЎAҰэұj«Ч§C,јціBІzӨЈҜаұjӨЖҘiӨБ«d©КӨЈҰnЎFҘi®рІkЎBІBӯмӨlІk©MұөДІІk,ӨЈ©цЧчІkЎF©ц©УЁьҰUәШАЈӨOҘ[Өu©MӨЮҰщЎBЕsҰұЎC | ||||||||||||

| Ёе«¬ҘОі~ Typical applications | ||||||||||||

| 1060јsӘxАіҘО©у№пұj«ЧӯnЁDӨЈ°ӘӘәІЈ«~.ЎCІЈ«~ұ`ҘО©у©ЫөPЎBјs§iөPЎB«ШҝvӘ«Ҙ~Ж[ёЛ№ўЎBӨҪЁ®Ё®ЁӯЎB°ӘјУ»PӨuјtщЩЁӯёЛ№ўЎBјp©Р¬~ә°јСЎBҝO®yЎBӯ·®°ёӯЎB№qӨlҘОҘуЎAӨЖӨu»цҫ№ЎBБЎӘOҘ[ӨuҘуЎBІ`©Ф©ОұЫАЈҘW§Оҫ№ҘЧЎBІkұө№sҘуЎBјцҘжҙ«ҫ№ЎBДБӘнӯұӨОҪLӯұЎB»КөPЎBјpЁгЎBёЛ№ў«~ЎBӨПҘъҘОЁгөҘЎC | ||||||||||||

| ӨЖҫЗҰЁҘчӨАӘR Chonioal composition | |||||||||||

| ҰXӘчөPё№Alloy | Цә Si | ЕK Fe | »Й Cu | ҝш Mn | Бв Mg | »М Cr | ҫN Zn | Ьg Ti | ЁдҘL Others | ҫT AL | |

| ЁCӯУ | ҰXӯp | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | 0.05 | 0.03 | 0.03 | ҫl¶q | ||

| ҫчұс©КҜаӨАӘR Mechanical properties | |||||||||||

| ҫTҰXӘчөPё№ӨОӘ¬әA Aluminium alloy & temper | §Ь©Фұj«Ч Rm/MpaTensile Strength | ©}ӘAұj«Ч Rp0.2/Mpa Proof Strength | В_«бҰщӘшІvЎAA/% Percentage elongation after fracture | өw«Ч HB Hardness | |||||||

| 1060-H24 | 105-145 | 75 | 3 | 33 | |||||||