| 品牌:尚榮合金 | 規格: | 材質:Fortal |

| 產地:法國 |

FORTAL?模具鋁合金板塊

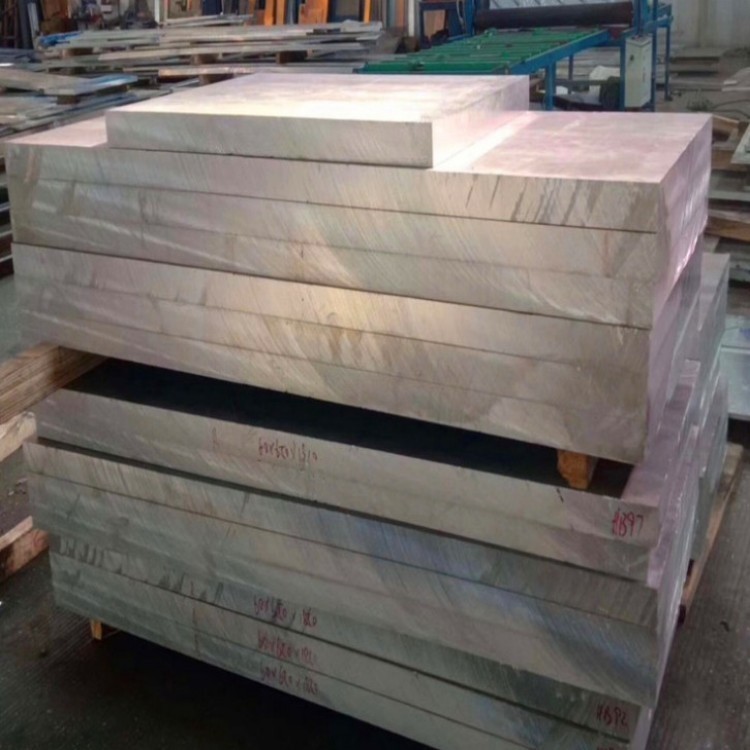

FORTAL是採用航空航天品質的鋁合金設計的,是為模具加工行業應用專ye開發的。FORTAL的開發人員知道,在這個行業中,核心材料非常關鍵,因為會從板的內部切出型腔,孔和鍵槽。FORTAL在材料的整個橫截面(內外相同)上具有一致的機械性能,從而超yue其他品牌的合金。FORTAL的兩個牌號FORTAL-HR和FORTAL-HP在任何所需的厚度下均可為用戶提供必要的性能。

FORTAL?aluminum mold block

FORTAL was designed from an aircraft aluminum and developed for the mold working industry. The developers of FORTAL knew that in this industry, the core material is very critical because of pockets, holes and keyways that will be cut from the interior of the plate. FORTAL exceeds other brands of this alloy by having extremely consistent mechanical properties throughout the crosssection of the material (its the same - inside and out).The two grades of FORTAL-HR & FORTAL-HP offer the user the necessary properties in whichever thickness is needed.

FORTAL?模具鋁概述:

FORTAL是高產量和原型模具應用的理想選擇。與傳統的模具鋼相比,通過使用較少的電極,縮短EDM的燃燒時間,機加工速度提升五倍,並且易於拋光,從而縮短了模具的交貨時間。在FORTAL的整個橫截面中,一致的材料特性使其成為進行深型腔加工的理想選擇。使用FORTAL可獲得具有出色耐磨性的部件。FORTAL吸收衝擊和振動的能力確保了成型零件的準確性,並降低了次品率。

FORTAL?Comparison(性能對照):

Fortal和 Alumold Ⅱ是法國普基Pechiney Rhenalu 開發的具有知識產權的產品,廣泛用作模具材料。與模具鋼相比,具有顯zhu的優點:

1. 重量輕。由於其密度只有一般模具鋼的36%,故運動慣性比較低,在生產過程中加,減速度均比較容易,能減低機器及模具的損耗。

2. 機械加工容易及尺寸穩定性高。其切削速度比一般模具鋼快6倍以上,故大量減低模具加工時間,令模具可更快進行生產。

3.卓yue的熱傳導率。其熱傳導率比一般模具鋼高,故可節省模具在生產時的冷切時間50%,從而提高模具的生產效率。

在注塑模、吹塑模、低壓模、橡膠模等不同模具行業80%的產品中有廣泛應用。隨著市場的發展,目前在歐美市場Alumold已替代鋼做模。

廣東Fortal鋁板供應商