| 品牌:尚榮合金 | 規格:齊全 | 材質:2024 |

| 產地:美國 |

材料介紹:(Alloy 2024)

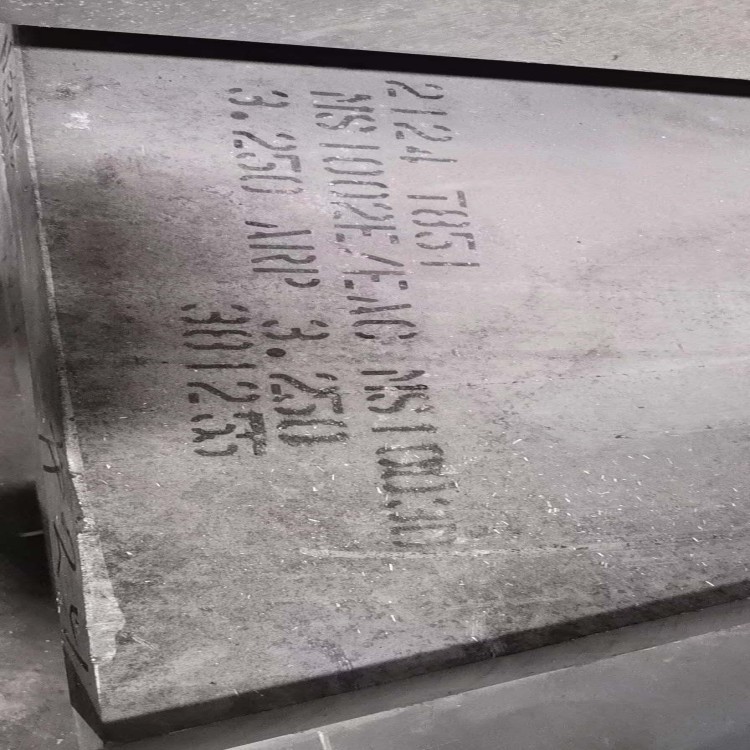

美鋁公司在1931年推出鋁合金2024包鋁表中的T3狀態。這是第yi次將Al-Cu-Mg係合金的屈服強度改善到50,000 psi,一般替代2017-T4(硬鋁合金)作為主要的2XXX係列飛機合金。憑借其相對良好的抗疲勞性,特別是在厚鋼板的形式,合金2024繼續被指定為許多航空航天結構應用程序中的主要合金。2024變式的合金,如純度較高的2124和2324,能夠改善飛機關鍵結構中的強度及其他具體特點。鋁合金2024在退火狀態在,包鋁薄板和中厚板產品呈現出T3,T4和T8的形式。2024合金板產品使用在機身結構鋼,機翼張力成員,剪切腹板和肋骨結構,及要求疲勞性能和強度良好的地方。片狀產品,通常是包鋁,廣泛用於商用和飛機的機身外觀,機翼蒙皮和發動機領域,要求適應升高溫度為250°F(121°C)的環境下。在T851的狀態下,2024具有非常良好的耐SCC性能。經淬火和人工控制老化的2XXX在熱處理強化之後能有效地改善其耐應力腐蝕開裂性能。2024-T351/2024-T851材料在超過20年的應用過程中,一直沒有出現SCC故障事件報告。

化學成分範圍:

Si | 0.30 | Zn . . . | 0.25 |

Fe . . . | 0.50 | Ti . . . | 0.15 |

Cu . . . | 3.8-4.9 | Others, each . . . | 0.05 |

Mn . . . | 0.30-0.9 | Others, total . . . | 0.15 |

Mg . . . | 1.2-1.8 | Balance, Aluminum | |

Cr . . . | 0.1 |

Note: Value maximum if range not shown

機械性能:

Temper | Thickness in. (mm) | TENSILESTRENGTH Ksi(Mpa) | YIEID STRENGTH Ksi(Mpa) | ELONGATION % |

0 | 0.015-2.00 | 202 (max) | 220 (max) | 10-12 |

Sheet & plate T3 | (0.38-50.80) 0.008-0.249 | (400-424) 40-42.4 | (269-276) 26.9-27.6 | 10-15 |

Sheet T351 | (0.203-6.32) 0.250-4.000 | (470) 470 | (280) 28 | 19 |

(ALLOY 2024 All values are minimum long transverse mechanical properties except where noted)

合金2024規範:

PLATE |

Temper T651 T7651 Specification QQ-A-250/13 QQ-A-250/24 MIL-HDBK-5 Approved |

BARE SHEET ALCLAD SHEET |

Specification QQ-A-250/12,24 QQ-A-250/13,25,26 MIL-HDBK-5 Approved Approved |

2024 2219 2618

*AIMS 03-02-004 *DSN 1105 *BS 2 L.97 *A5-SA-121-1039 *ABM 1-1006

*ABM 1-1005 *SMS 3204 *FMS 3008 *AMS 4295 *AIMS 03-02-021

*AIR 9048 *TH 5.312 *BS 2 L.98 *AMS-QQ-A-250/30 *AIR 9048

*AMS 4037 *WL 3.13542214 *MMS 149 *DSN 1719.01 *ASN-A 3355

*AMS 4041 *AIR 9048 *C.R. 1.1.0.36 *SA-MU-42.549.04 *BAEM 1103

*AMS-QQ-A-250/4 *C.R. 1.1.0.31 *MEP 02-029 *DAN 422

*AMS-QQ-A-250/5 *AMS 4101 *DAN 422

*ASN-A3011 *AMS-QQ-A-250/29 *FMS 3002

*BAEM 1033

1:鋁業協會標準和數據。2:鋁業協會,斷裂韌性的位置要求和質量控制測試T-5。

3:MIL-H-6088,鋁合金的熱處理。

1. The Aluminum Association, Standards and Data.2. The Aluminum Association, Position on Fracture Toughness Requirements and Quality Control Testing T-5.

3. MIL-H-6088, Heat Treatment of Aluminum Alloys.

美國2024鋁板 韓國2024鋁板現貨