6061¶iӨfҫTәЮ 6061ҫTәЮ6061¶iӨfҫTәЮ 6061ҫTәЮ6061¶iӨfҫTәЮ 6061ҫTәЮ6061¶iӨfҫTәЮ 6061ҫTәЮ6061¶iӨfҫTәЮ 6061ҫTәЮ ӨЖҫЗҰЁӨАЎF өPё№ ӨЖҫЗҰЁӨА ЦәSi »ЙCu БвMg ҫNZn ҝшMn ЬgTi »М Cr ЕKFe ҫTAl 6060ҫTҰXӘч 0.30-0.6 0.10 0.35-0.6 0.15 0.10 0.10 0.05 0.10~0.30 ҫl¶q 6061ҫTҰXӘч 0.4-0.8 0.15-0.4 0.8-1.2 0.25 0.15 0.15 0.04-0.35 0.7 ҫl¶q 6063ҫTҰXӘч 0.20-0.6 0.10 0.45-0.9 0.10 0.10 0.10 0.10 0.35 ҫl¶q 6063AҫTҰXӘч 0.30-0.6 0.10 0.6-0.9 0.15 0.15 0.10 0.05 0.150-0.350 ҫl¶q ҰXӘч ЦәSi ЕKFe »ЙCu ҝшMn БвMg »МCr ҫNZn ЬgTi ЁдҘҰ ҫT ЁCӯУ Б`ӯp ӨpӯИ 6061 0.4-0.8 0.7 0.15-0.4 0.15 0.8-1.2 0.04-0.35 0.25 0.15 0.05 0.15 ҫl¶q ҫчұс©КҜаӨАӘR(Typical Mechanical Properties) ҫTҰXӘчөPё№ӨОӘ¬әA ©ФҰщұj«Ч ©}ӘAұj«Ч өw«Ч ©өҰщІv (25ўXC MPa) (25ўXC MPa) 500kgӨO10mmІy 1.6mm(1/16in)«p«Ч ALLOY AND TEMPER Ultimate Tensile Strength Tensile Yield Strength Hardness Elongation 6061-T6 / 6061-T651 310 276 95 12 Ә«Іz©КҜаӨАӘR(Typical Physical Properties) ҫTҰXӘчөPё№ӨОӘ¬әA јцҝұөИ«YјЖ(20-100ўJ)Јgm/mЎPk әІВIҪdіт(ўJ) №qҫЙІv20ўJ(68ўK) №qӘэІv20ўJ(68ўK) ALLOY AND TEMPER Average Coefficient Of Thermal Expansion Approximate Melting Range Electrical Conductivity Electrical Resistivity 6061-T6/6061-T651 23.6 580-650 43 0.040 6«YҰCҫTҰXӘчҘОі~ЎG 6005 АҪАЈ«¬§ч»PәЮ§чЎAҘО©уӯnЁDұj°ӘӨj©у6063ҰXӘчӘәөІәcҘуЎAҰpұиӨlЎB№qөшӨСҪuөҘ 6009 ЁTЁ®Ё®ЁӯӘO 6010 БЎӘOЎGЁTЁ®Ё®Ёӯ 6061 ӯnЁDҰіұj«ЧЎBҘiІk©К»P§Ь»k©К°ӘӘәӨu·~өІәc©КЎAҰpЁоіyҘdЁ®ЎB¶рҰЎ«ШҝvЎBІоІнЎB№qЁ®ЎB®aЁгЎBҫчұс№sҘуЎBәлұKҘ[ӨuөҘҘОӘәәЮЎBҙОЎB§О§чЎBӘO§чЎC 6062 јsӘxАіҘО©уӯnЁDҰіұj«Ч©M§ЬөЯҜА»k©К°ӘӘәӨu·~өІәcҘуЎAҰpЁоіyҘdЁ®ЎA¶рҰЎ«ШҝvЎAІоІнЎA№qЁ®ЎAЕK№DЁ®ҪшЎA®aЁгөҘёУҰXӘчӨӨӘәҘDӯnҰXӘчӨёҜА¬°БвӨОЦәЎAЁгҰіӨӨөҘұj«ЧЎAЁ}ҰnӘә§Ь»G»k©КЎAҘiІkұө©КЎA®сӨЖ®ДӘGҰn 6063 «Шҝv«¬§чЎAДйө@әЮ§чҘHӨОЁСЁ®ҪшЎB»O¬[ЎB®aЁгЎBДж¬]өҘҘОӘәАҪАЈ§ч®Ж 6066 БлҘуӨОІkұөөІәcАҪАЈ§ч®Ж 6070 ӯ«ёьІkұөөІәc»PЁTЁ®Өu·~ҘОӘәАҪАЈ§ч®Ж»PәЮ§ч 6101 ӨҪҰ@ЁTЁ®ҘО°Әұj«ЧҙО§чЎB№qҫЙЕй»PҙІјцҫ№§чөҘ 6151 ҘО©ујТБлҰұ¶b№sҘуЎBҫчҫ№№sҘу»PҘНІЈӘоЁоАфЎAЁС¬JӯnЁDҰіЁ}ҰnӘәҘiБл©КҜаЎB°ӘӘәұj«ЧЎAӨSӯnҰіЁ}Ұn§Ь»k©КӨ§ҘО 6201 °Әұj«ЧҫЙ№qҙО§ч»PҪu§ч 6205 «pӘOЎBҪсӘO»Pӯ@°ӘҪДА»ӘәАҪАЈҘу 6262 ӯnЁD§Ь»k©КАu©у2011©M2017ҰXӘчӘәҰіБіҜҫӘә°ӘАіӨO№sҘу 6351 Ё®ҪшӘәАҪАЈөІәcҘуЎAӨфЎBҘЫӘoөҘӘәҝй°eәЮ№D 6463 «Шҝv»Pҫ№Ёг«¬§чЎAҘHӨОёg¶§·Ҙ®сӨЖіBІz«бҰі©ъ«GӘнӯұӘәЁTЁ®ёЛ№ўҘу 6A02 ӯёҫчөo°Кҫч№sҘуЎA§ОӘ¬ҙ_ВшӘәБлҘу»PјТБлҘу ІЈ«~§чҪиГТ©ъЎG §ЪӯМӘә©УҝХЎGӨЈ°өӨЈЁ}«~ЎC ЕwӘпұzӯМӘәЁУ№qЎC

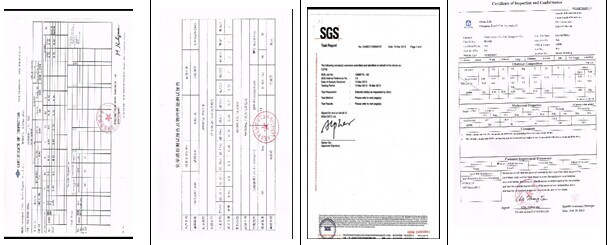

ЁУД_јt®aҘDАз¶iӨf¬ь°кӘвҘiјЦҫTҰXӘч ӯ@ҝiҫTӘO Ҙъ«GҫTҰXӘчГҜӘO °Әөw«ЧҫTҙО ¶§·Ҙ®сӨЖҫTәЮ Өu·~ҜВҫTұa ҜВҫTӘOҜиӘЕ¶WөwҫTӘO Ҙ[өwҫTҙО ¶WөwҫTҰXӘч ГиӯұҫTӘO °ӘҜВҫTӘO °Әұj«ЧҫTҙО °Ә¶ҙ©КҫTҪuҫTұa ҫTЁч¬ь°кALCOA 6061-T6/6061T651 әлұKҘ[ӨuҘОҫTҰXӘчӘO

ӨЖҫЗҰЁҘчӨАӘR(Chemical ComPOSTTTION Limit Of Aluminum Alloys)

өPё№

(%IACS)

Ј[mm2/m

ҘНІЈ¬yө{№ПЎG

Ҙш·~ӨеӨЖЎG

ҰЫҰЁҘЯҘHЁУЎAЁУД_Ө@ӘҪ°н«щӨО§VӨO№кІ{ӘәЎAҙN¬OВІіжӨОҙоӨЦБcӨекРё`Әә¶°№ОҘш·~ӨеӨЖЎCҙxҙӨЁ¬°чӨОҰXҫAӘә«H®§ЎAҫA®Й§@ҘXЁM©wЎA¬O¶°№О°нҰuӘәӯ«ӯnӯм«hЎC°нҰuҝn·Ҙ¶iЁъӘәәA«ЧӨОЎuЁSӘFҰиҘiДdЁмЎvӘәјЦЖ[әлҜ«ЎA«ШҘЯ©ъҪTҘШјРЎA§в¬DҫФөш¬°ҫч·|ЎAҘзұjҪХӨu§@ӨОҘжҘI¶өҘШӘәҘж©ц«~ҪиЎAҝнұq№DјwҫЮҰuЎA§уҘHӘш»·ІҙҘъӨОЖF¬Ў«дәыЎA»P®ЙЁГ¶iЎCЁӯЕйӨOҰжЎAҰbӨйұ`ҘН¬Ў©MӨu§@ӨӨ№кҪо¶°№ОӘәӨеӨЖӨО»щӯИЎAҰУ¶°№ОӘәҰж¬FӨHӯыӨОәЮІzӨHӯыҘз·|ҘHЁӯ§@«hЎA№ӘАyӯыӨuҝn·Ҙ№кҪоіoЁЗ«H©АЎC