| «~µPˇG©|şa¦XŞ÷ | łW®ćˇGŻS®íłW®ćĄi©w¨î | §÷˝čˇGQC-10 |

| ˛Ł¦aˇG¬ü°ę |

QC-10ľTŞO§ĺµo°Ó ĄiĄN«Č¤Á¤ůĄ[¤uQC-10ľTŞO§ĺµo°Ó ĄiĄN«Č¤Á¤ůĄ[¤uQC-10ľTŞO§ĺµo°Ó ĄiĄN«Č¤Á¤ůĄ[¤u

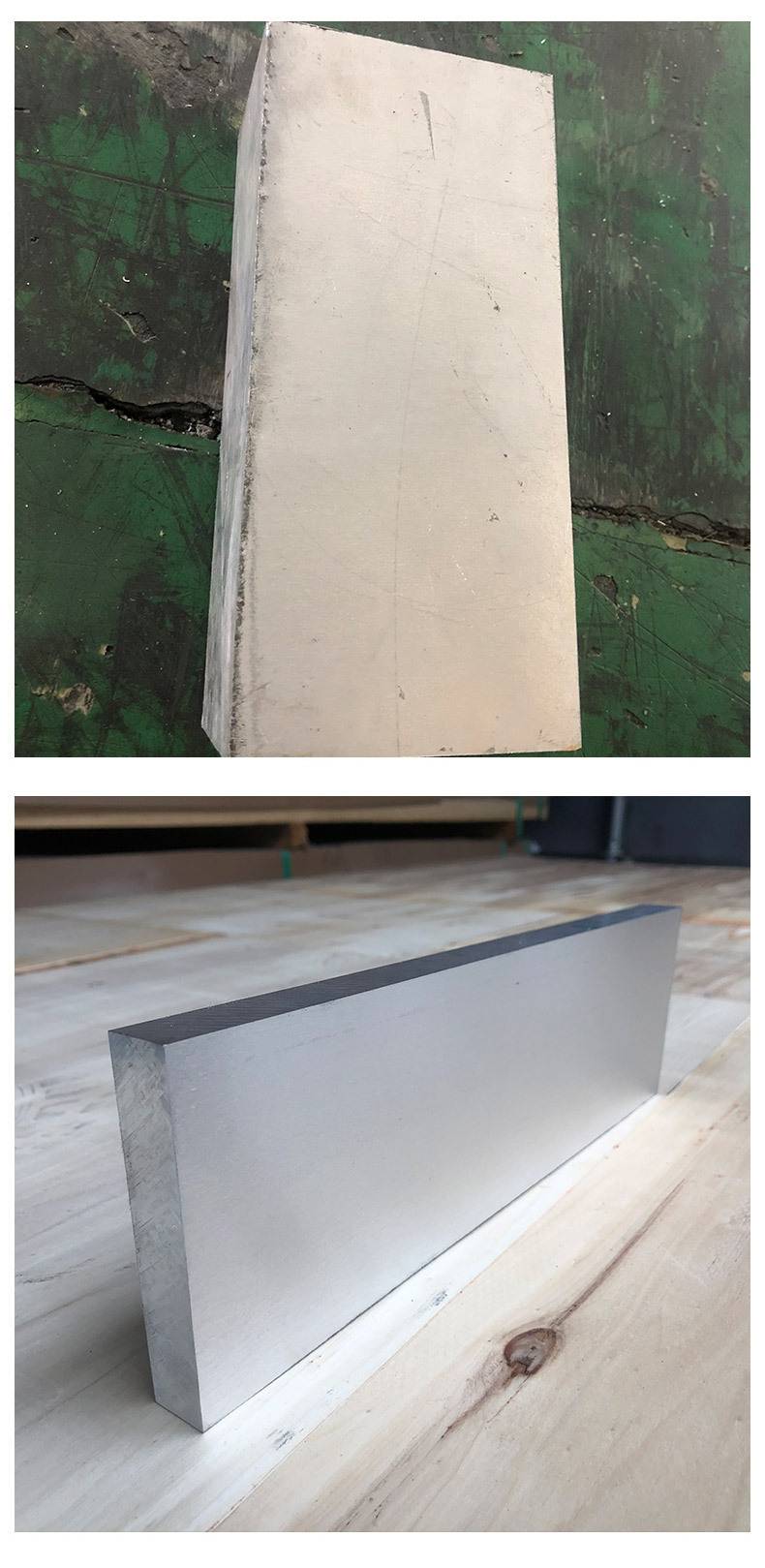

QC-10ĽŇ¨ăľT¦XŞ÷ŞO¶ô

ŔHµŰ¬ü°ęľT·~¤˝Ąq·s¤@ĄNĽŇ¨ă¦XŞ÷Şş°ÝĄ@ˇXˇXQC-10ÂX®i¤FĽŇ¨ăł]p¤č®×ˇAALCOA¬üľT¤˝Ąq¦bQC-10¤Wąę˛{¤FŻŕ°÷§ĺ¶q¨îłyŞş·sŞş©ĘŻŕˇCĄ¦ŞşĄ[¤u®Ä˛v¤ńżű§÷§Ö8-10żˇAĄ[¤u¦¨Ą»©MĄćłf®É¶ˇÁYµu¤F20˘H¨ě30˘HˇCĄtĄ~ˇAĄ¦ŞşľÉĽöłt«×¬OP-20¤u¨ăżűŞşŞń5żˇAÁYµu¤F20˘H¦Ü40˘HŞşĄÍ˛Ł©P´Á®É¶ˇˇC

QC-10 aluminum mold block

As Alcoaˇ¦s next generation mold alloy, QC-10 expands mold design options and brings new performance capabilities to high volume manufacturing. It machines 8-10 times faster than steel, reducing finishing costs and lead times by 20-30%.Plus it conducts heat nearly 5 times faster than P-20 tool steel, shorting production cycle times by 20-40%.

QC-10ĽŇ¨ăľT·§zˇG

ąď©óĽŇ¨ă¨îły°ÓˇAQC-10¦łµŰĹăµŰŔu©ó¤u¨ăżűŞş¦nłBˇAĄ¦ĚŻŕ°÷ÂX®ił]p¤č®×ˇA¨Ă§QĄÎ¨ä ŞşĽö©ĘŻŕ©Mľ÷±ńĄ[¤u©ĘŻŕˇAĄH´Ł°ŞĽŇ¨ăĄÍ˛Ł®Ä˛vˇC

¦bĄ[¤uąLµ{¤¤ˇAľT©úĹă´î¤Ö¤FĄ[¤u®É¶ˇˇC¦ÓĄBˇA¦bĄ[¤uąLµ{¤¤˛ŁĄÍŞşĽö¶q¤jłˇ¤Ŕ°±Żd¦b¤Á®h¤¤ˇA±q¦Ó¨Ď¤Á«d¤M¨ă¤´«OŻd¦yľUˇA¨ĎĄÎąŘ©R§óŞřˇC¤Ł¶Č¦p¦ąˇAľTŞş˝č¶q§ó»´ˇAĄ¦Şş±K«×¬OżűŞş¤T¤Ŕ¤§¤@ˇA¨Ď±oĄ¦§ó®e©ö¤č«KąBżé¤ÎşŢ˛zˇC

QC-10 Comparison(©ĘŻŕąď·Ó)ˇG

ĽŇ¨ă§÷®Ć | ľÉĽö«YĽĆ BTU/ft-hr-˘XF | ±K«× lb/in3 |

µw«× | ©}ŞA±j«×(ksi) | Ľöż±µČ«YĽĆ Łgin/in-˘XF | |

QC-10 | 7xxx Aluminum | 92.2 | 0.103 | 150-170 HB | 66 - 76 | 13.7 |

QC-7 | 7xxx Aluminum | 91 | 0.102 | 167 HB | 74-79 | 12.8 |

7075-T651 | 7xxx Aluminum | 75 | 0.101 | 150 HB | 48-73 | 13.1 |

6061-T651 | 6xxx Aluminum | 96 | 0.098 | 95 HB | 40-42 | 13.1 |

2618 T6 | 2xxx Aluminum | 102 | 0.101 | 95 HB | 28-30 | 12.9 |

P20 Grade Steel | Carbon Steel | 20 | 0.285 | 28-36 Rc | 130-135 | 7.1 |

MoldMax HH? | Beryllium Copper | 75 | 0.302 | 40 Rc | 140-145 | 9.7 |

QC-10ĽŇ¨ăľTŞO©MÁëłyľTŞO¶ô

»PĄ«±¤WĄô¦ó¨äĄL7000«Y¦CľTĽŇ¦XŞ÷¬Ű¤ńˇA±M¬°ĄÍ˛ŁŞ`ĽŇ¦Ół]pŞşQC-10¨ăłĆ§ó¤j±j«×ˇB§ó°ŞĂ©w©Ę©M§óĄiľaŞş@¤[©ĘˇC¦bąď¦XŞ÷¦¨¤Ŕ¶i¦ć§ď¶i¤§«áˇAQC-10ŞşşI±±j«×©Mµw«×Şí˛{·Ą¬°ĄX¦âˇA¦Ó¨ä˛f¤ő¤Ł±Ó·PŞş·L«¬µ˛şcĄ»¤Ł·|°§CşI±±j«×ˇA¨Ă¨ăłĆŞş¤Á«dĄ[¤u©ĘŻŕˇC

ŔłĄÎĽsŞx

QC-10¬OľAĄÎ©óĄÍ˛ŁĽŇ¨ăŔłĄÎŞş˛z·QĽŇ¨ă§÷®ĆˇAĽsŞxŔłĄÎ©ó¨T¨®ˇB®ř¶Oąq¤l©M¤u·~˛Ł«~µĄ¦UÓ¦ć·~ˇCQC-10ŞşĄ[¤ułt«×§Ö©óżű§÷ˇA¨Ă¤ä«ůąq¤őŞáĄ[¤uˇB©ßĄú©MŻľ˛zĄ[¤uˇC

Ą[¤ułt«×§ó§Ö

§@¬°¤@şŘ°Şµw«×ľTĽŇ§÷®ĆˇA¦b˛Ę»ŃĄ[¤uąLµ{¤¤ˇAQC-10ŞşĄ[¤ułt«×¬Ożű§÷Şş8-10żˇC¨ĎĄÎ°ŞłtĄD¶bŞş±řĄó¤UˇAQC-10˛ĘĄ[¤uĄiĄHąF¨ě20,000rpmŞş¤ÁłÎłt«×©M0.325mmptŞş¶iµą¶qˇC¬üľTŻS¦łŞşŔł¤O§NĄ[¤u§ŢłN¨ĎQC-10¦bľăӼҶô¤¤«O«ůĂ©wŞş±j«×ˇA±q¦Ó¨Ď¨ä±q¨äĄLľT¦XŞ÷§÷®Ć¤¤˛ćżo¦ÓĄXˇC¨Ň¦pˇA»PP20żű§÷¬Ű¤ńˇAĄŃ©ó˛ĘĄ[¤uŞşłt«×±o¨ě´Ł¤ÉˇAĽŇ¨ăĽt°ÓŻŕ°÷±NĽŇ¨ă¨îłyŞşĄćłf´ÁÁYµu40%ˇC

©P´Á§óµu

ŞşĽö¶ÇľÉ©ĘąďÁYµu©P´Á·Ą¬°ĂöÁäˇCQC-10ľÉĽöłt«×¬O¤u¨ăżűŞşŞń5żˇA¨Ď±o¨îĽŇ©P´ÁÁYµu20-50%ˇCÁYµu©P´Á§Y´Ł°Ş¤F˛ŁŻŕˇCĄŃ©óQC-10¤ń¤u¨ăżűĄ[Ľö©Î§N«o§ó§ÖˇAĄ[¤u¬yµ{§óĄ[ˇAĄB´î¤Ö¤FąďŞ`¶ěłˇĄóĹܧΰÝĂDŞşľáĽ~ˇC

«ŘĽŇ¦¨Ą»§ó§C

QC-10łqąL±NŞ`¶ě©P´ÁÁYµu20-50%ˇA±q¦Ó¬°¨îły°Ó±a¨Ó©úĹ㪺¦¨Ą»Ŕu¶ŐˇCŞ`ĽŇŞ`¶ěłˇĄó50%Şş¦¨Ą»·˝©ó©P´ÁˇCÁYµu©P´Á§YĄiĽWĄ[˛Ł¶qˇA°§C¦¨Ą»ˇC¤@®a¨îły°Ółř§iŞíĄÜ¨ĎĄÎQC-10«áˇAĄLĚĄÎĄ|¤Ń®É¶ˇ´NąF¨ě¤F¤¤ŃŞş˛Ł¶qˇA±q¦Ó±NÄŔ©ńĄXŞş˛ŁŻŕ§ë¤J¨ě·s¤u§@¤¤ˇC

¤[¸gĹçĂŇŞş©Ę

¤µ¤ŃˇAł\¦hQC-10ĽŇ¨ăŞşŞ`¶ě¦¸ĽĆ¤wąF¨ě50¸U¦h¦¸ˇA¦ł¨ÇĄżąGŞńĽĆ¦r100¸U¦¸ˇC·íµMˇAn«OĂҼҨă¦bľăÓĄÍ©R©P´Á¤şŞşĂ©w©ĘˇA«h»Ý¶i¦ćŞş©w´ÁşűĹ@ˇC¨S¦ł¤HĽÖ©óşű׼ҨăˇA¦Ó°wąď»Ýnşűתş±ˇŞpˇA¬üľT¶}µo¤F±M¦łŞş×¸É˛kµ·ĄÎ©ó¤Ç°tĽŇ¨ă¤ĆľÇ¦¨¤ŔˇC˝Đ«t¸ß¬üľT§ŢłN¤Hű¤F¸Ńşűק޳NˇC