| «~µPˇGŞâĄiĽÖ | łW®ćˇG | §÷˝čˇGĽĐ·Ç |

| ˛Ł¦aˇG¬ü°ę |

ŞF·~¤j©ÝľT§÷¨Ć·~łˇ§ĺµo¶i¤fALCOA¦XŞ÷ľTˇAĽŇ¨ăľTˇAQC-10ˇAQC-7ˇAAlumec89

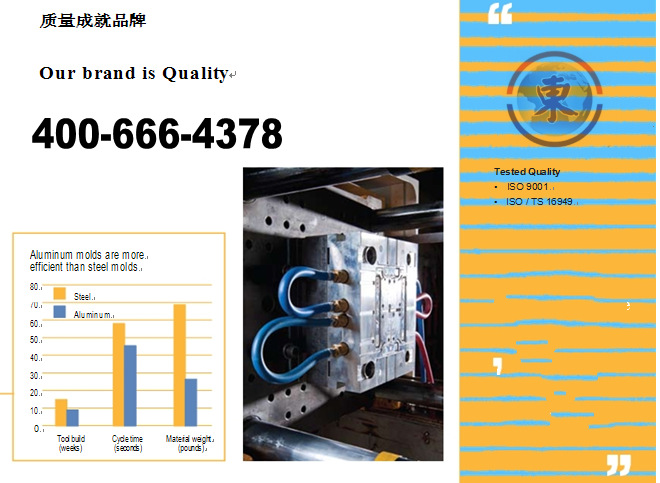

ŔHµŰ¬ü°ęľT·~¤˝ĄqŞş·s¤@ĄNĽŇ¨ă¦XŞ÷ˇXˇXQC-10ÂX®iĽŇ¨ăł]p¤č®×Şş°ÝĄ@ˇAALCOA¬üľT¤˝Ąq±a¨Ó¤F·sŞşĽŇ¨ăľT§÷Şş§ĺ¶q¨îłyˇAĄ¦Şş¤u§@ľ÷˛v¤ńżű§÷§Ö8-10żˇA¤ńżű°§CľăĹ馨Ą»©MĄćłf®É¶ˇ20˘H¨ě30˘HˇCĄtĄ~ˇAĄ¦ŞşľÉĽö©Ęłt«×¬OP-20¤u¨ăżűĹKŞşŞń5żˇAÁYµu¤FĄÍ˛Ł©P´Á¬ů20˘H¦Ü40˘HŞş®É¶ˇˇC

![]()

§÷®Ć²zˇG

ąď©óĽŇ¨ă¨îły°ÓˇAQC-10¦łµŰĹăµŰŔu©ó¤u¨ăżűŞş¦nłBˇAĄLĚŻŕ°÷ÂX¤jĄLĚŞşł]p¤č®×ˇA¨Ă§QĄÎ¨äµL»PۤńŞşĽö©ĘŻŕ©Mľ÷±ńĄ[¤u©ĘŻŕˇA¨Ď±oĽŇ¨ă¤Á«d§ó¨ă®Ä˛vˇC

¦bĄ[¤uąLµ{¤¤ˇAľT©úĹă´î¤Ö¤FĄ[¤u®É¶ˇˇC¦ÓĄBˇA¦bĄ[¤uąLµ{¤¤ˇAĄŃ©ó¦í±JĽö¶qĄDn¬O¦bŞä¤ůˇA¤M¨ă¤Á«d¤´Żd¦yľUˇA¨ĎĄÎąŘ©R§óŞřˇC¤Ł¶Č¦p¦ąˇAľTŞş˝č¶q§ó»´ˇAĄ¦Şş±K«×¬Oč±o¤T¤Ŕ¤§¤@ˇA¨Ď±oĄ¦§ó®e©ö¤č«KąBżé¤ÎşŢ˛zˇC

QC-10CompArisoN(QC-10¦¨¤Ŕąď·Ó)ˇG

QC-10 | 7xxxAluminum | 92.2 | 0.103 | 150-170 HB | 66 ˇV 76 | 13.7 |

7075 - T651 | 7xxx Aluminum | 75 | 0.101 | 150 HB | 48-73 | 13.1 |

6061 - T651 | 6xxx Aluminum | 96 | 0.098 | 95 HB | 40-42 | 13.1 |

2618 T6 | 2xxx Aluminum | 102 | 0.101 | 95 HB | 28-30 | 12.9 |

p20 Grade steel | Carbon steel | 20 | 0.285 | 28-36 rc | 130-135 | 7.1 |

moldmax HH | BerylliumCopper | 75 | 0.302 | 40 rc | 140-145 | 9.7 |

QC-10? Aluminum Mold Alloy

QC-10? Mold Plate and Forged Block

»PĄ«±¤WĄô¦ó¨äĄL7000«Y¦CľT¶ě¦XŞ÷¬Ű¤ńˇA±M¬°ĄÍ˛ŁŞ`ĽŇ¦Ół]pŞşQC-10¨ăłĆ§ó¤j±j«×ˇB§ó°ŞĂ©w©Ę©M§óĄiľaŞş@¤[©ĘˇC¦bąď¦XŞ÷¦¨¤Ŕ¶i¦ć§ď¶i¤§«áˇAQC-10ŞşşI±±j«×©Mµw«×Şí˛{·Ą¬°ĄX¦âˇA¦Ó¨ä¤Ł±Ó·PŞşµw¤Ć·L«¬µ˛şc°ňĄ»¤Ł·|°§CşI±±j«×ˇA¨Ă¨ăłĆµL»PۤńŞş¤Á«d©ĘŻŕˇC

ĄÓ˝Đ

QC-10¬OľAĄÎ©óĄÍ˛Ł¤u¨ăŔłĄÎŞş¨ÎĽŇ¨ă§÷®ĆˇAĽsŞxŔłĄÎ©ó¨T¨®ˇB®ř¶Oąq¤l©M¤u·~˛Ł«~µĄ¦UÓ¦ć·~ˇCQC-10ŞşĄ[¤ułt«×§Ö©óżű§÷ˇA¨Ă¤ä«ůąq¤őŞáĄ[¤uˇB©ßĄú©M«rŞáˇC

Ą[¤ułt«×§ó§Ö

§@¬°¤@şŘ°Şµw«×ľT¶ě§÷®ĆˇA¦b¨ĎĄÎ˛ĘŞîľ÷Şş±ˇŞp¤UˇAQC-10ŞşĄ[¤ułt«×¬Ożű§÷Şş8-10żˇC¨ĎĄÎ°ŞłtĄD¶bŞş±řĄó¤UˇAQC-10˛ĘĄ[¤uĄiĄHąF¨ě20,000 rpmŞş¤ÁłÎłt«×©M0.325 mmptŞş¶i®Ć¶qˇC¬üľTŞşŻS¦łŔł¤O(Signature Stress Relief)§NĄ[¤u§ŢłN¨ĎQC-10¦bľăӼҶô¤¤«O«ůĂ©wŞş±j«×ˇA±q¦Ó¨Ď¨ä±q¨äĄLľT¦XŞ÷§÷®Ć¤¤˛ćżo¦ÓĄXˇC¨Ň¦pˇA»PP20żű§÷¬Ű¤ńˇAĄŃ©ó˛ĘĄ[¤uŞşłt«×±o¨ě´Ł¤ÉˇAĽŇ¨ăĽt°ÓŻŕ°÷±NĽŇ¨ă¨îłyŞş´Ł«e´ÁÁYµu40%ˇC

©P´Á§óµu

ŞşĽö¶ÇľÉ©ĘąďÁYµu©P´Á·Ą¬°ĂöÁäˇCQC-10ľÉĽöłt«×¬O¤u¨ăżűŞşŞń5żˇA¨Ď±o¨îĽŇ©P´ÁÁYµu20-50%ˇCÁYµu©P´Á§Y´Ł°Ş¤F˛ŁŻŕˇCĄŃ©óQC-10¤ń¤§¤u¨ăżű¤É·Ĺ©Î§N«o§ó§ÖˇAĄ[¤u¬yµ{§óĄ[ˇAĄB´î¤Ö¤FąďŞ`¶ěłˇĄóĹܧΰÝĂDŞşľáĽ~ˇC

łć»ů§ó§C

QC-10łqąL±NŞ`¶ě©P´ÁÁYµu20-50%ˇA±q¦Ó¬°¨îły°Ó±a¨Ó©úĹ㪺¦¨Ą»Ŕu¶ŐˇCŞ`ĽŇŞ`¶ěłˇĄó50%Şş¦¨Ą»·˝©ó©P´ÁˇCÁYµu©P´Á§YĄiĽWĄ[˛Ł¶qˇA°§Cłć»ůˇC¤@®a¨îły°Ółř§iŞíĄÜ¨ĎĄÎQC-10«áˇAĄLĚĄÎĄ|¤Ń®É¶ˇ´NąF¨ě¤F¤¤ŃŞş˛Ł¶qˇA±q¦Ó±NÄŔ©ńĄXŞş˛ŁŻŕ§ë¤J¨ě·s¤u§@¤¤ˇC

¤[¸gĹçĂŇŞş©Ę

¤µ¤ŃˇAł\¦hQC-10ĽŇ¨ăŞşĹ±Ąó¦¸ĽĆ¤wąF¨ě500,000¦h¦¸ˇA¦ł¨ÇĄżąGŞńĽĆ¦r1,000,000¦¸ˇC·íµMˇAn«OĂҼҨă¦bľăÓĄÍ©R©P´Á¤şŞşĂ©w©ĘˇA«h»Ý¶i¦ćŞş©w´ÁşűĹ@ˇC¨S¦ł¤HĽÖ©óşű׼ҨăˇA¦Ó°wąď»Ýnşűתş±ˇŞpˇA¬üľT¶}µo¤F±M¦łŞş×¸É˛kµ·ĄÎ©ó¤Ç°tĽŇ¨ă¤ĆľÇ¦¨¤ŔˇC˝Đ«t¸ß¬üľT§ŢłN¤Hű¤F¸Ńşűק޳NˇC

![]()

![]()

Ą[¤uŞA°ČˇG

Ąý¶iŞşCNCż÷»ŃĄ[¤u¤¤¤ßĄiĄHĄÍ˛ŁĄX˛Ĺ¦X«Č¤á»ÝnŞşŻS®í§ÎެĄH¤Î¬°´_ÂřŞşĄ~§ÎˇCĄtĄ~ˇAłćżWĄ[¤u¦Ó¦¨ŞşŞO§÷Ąi±a¦ł¨ă¦łşë±K¤Ř«×Şş©T©w¤ŐˇA¤Ř¤o±q6¦Ü45 mm (0.24ˇ¨¦Ü0.177ˇ¨)¤ŁµĄˇCĄ¦Ě¬O±aŔôÁł®ęŞş§Öłtłs±µ©M©T©w¸Ë¸mˇC§ÚĚĄi´Ł¨ŃľTŞOąwĄ[¤uˇAĄH¦ą¤jµ{«×¦a°§C«Č¤á¤čŞş¦¨Ą»©MĽo®ĆłB˛zˇC¸g¤Ř¤oşëפιwĄ[¤uŞşłˇĄóĄiłQ´Ł¨ŃµąĄţŞşĽs¤j«Č¤áˇC§ÚĚŞşŞA°ČÁŮĄ]¬A±N§÷®Ć¤ÁłÎ¦¨«Č¤á»ÝnŞşŞř«×ˇB®ć§˝«Č¤án¨D¶i¦ćĽĐĂŃĄH¤ÎĄ]¸ËˇC

©Ô¦ůˇB¶WÁnŞiŔË´úˇBľÉąq©ĘŔË´úˇB¦Ń¤ĆˇBż÷»Ń¤Î©ßżi¬°¤F´Ł°ŞŞO§÷ŞşĄľă«×¨Ă°§CłŃľl¤O,ŞO§÷±NłqąL¤TÓĄiżďŞş©Ô¦ůľ÷ˇ]¤j©Ô¤O8,000ľ·ˇ^¤¤Şş¤@ÓŔł¤OˇC

¦b©Ô¦ůłB˛z¤§«á§QĄÎ´ő¬y±´´ú¶i¦ćľÉąq©ĘŔË´úĄHŔˬdĽöłB˛z¬yµ{Şş§ˇ˝č©ĘˇAŔł¨ĎĄÎ¨â°ĽĄţ¦Ű°Ę±˝´yľô©Î˛ľ°Ę¦ˇŔË´úł]łĆˇC